We bring you the second half of our interview with Eton Tsuno, director of coffee at Temple Coffee Roasters, as he talks to us about Temple’s new roasting facility and their collaboration with Boyd Guildner of Renegade Roasters.

BY SARAH RICHMOND

BARISTA MAGAZINE ONLINE

In the second half of our interview with Eton Tsuno, he delves deep into the new roaster built for Temple Coffee Roasters. The roaster—a collaboration with Renegade Roasters’ Boyd Guildner—features innovations that will improve coffee roasting, increase consistency, and provide positive environmental contributions. Read part one of our interview here.

Sarah Richmond: Tell us EVERYTHING about this new roaster you’ve been working on!

Eton Tsuno: The new roaster is going to be the first of its kind in many ways. It’s the dream child of Boyd Guildner (Renegade Roasters and Ponderosa Roaster Maintenance) and myself. We have been talking for four years or so about a larger roaster for Temple. Over the past several years, we have come up with some crazy things, and a lot of, “Wouldn’t it be cool if …” ideas. The 60 kg plant Boyd is creating for us is a culmination of all these conversations.

Besides that, the automation software (Boyd’s own rebel controls) actually works. The automation and profiling capabilities of the machine repeats roasts time after time, even when batch sizes vary. Of course you can take it out of auto and into manual control at any point, but why when the software is so intelligent? Software and automation that actually does what you want and tell it to do is not only ideal for consistency, but also for profiling. For example, if you think you were about half a degree off at some point during roast, due to rate of rise, just tell the computer to do two degrees per minute there, with 25 percent burner, instead of tapping and adjusting gas knobs to try to correct it. Both Boyd and I agree that great automation isn’t the end of the craft, rather, when it’s used correctly, it allows us to achieve accurate results in the cup and perfect profiles with zero error.

The drum drive motor and gear box, cooling fan motor, and roaster airflow motor are all typical of a 120 kg or larger roaster. Some say this kind of power is overkill, but I believe it is just right. If you oversize motors, gear boxes, etc. on any roaster and have the ability to control them, the load on the motors will never be anywhere close to capacity. This means longer life, less maintenance, and in the end, more efficiency. Not to mention, a cooling fan like this, on a 60 kg roaster, will cool full batches of coffee in less than two minutes.

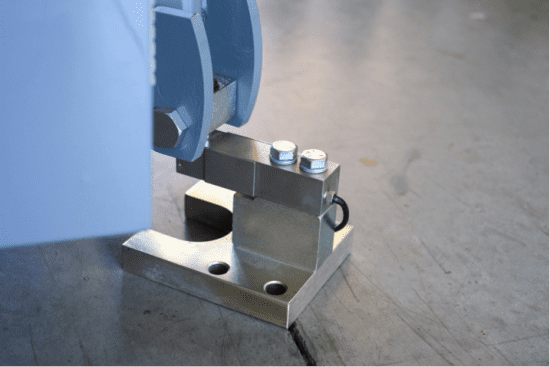

However, the two most exciting developments about the roaster are that the entire roaster is on load cells, which essentially makes the roaster a highly accurate scale. Additionally, we are in the process of permitting a wet scrubber for pollution control instead of using an afterburner.

SR: What does this mean for your roasting operations?

ET: Load cells on the roaster make it possible for us to measure the actual weight of the green coffee going in and roasted coffee coming out, as well as accurately measure weight loss during roasting. This real-time data will feed back to the roaster software and be displayed on our roasting charts, giving us the capability to influence our automation controls.

For roasting, this is going to be a game changer. As we know, most of the weight loss that occurs during roasting is actually moisture loss. Also, many of the desirable chemical reactions that lead to great flavor throughout different times in roast development require some moisture to occur.

We know that slowing down or speeding up (roast time), more or less airflow, faster or slower drum speed, and different combinations of all of these things during different periods in roast development change cup profile. Therefore, one can only assume that weight loss also occurs differently given different roasting environments.

SR: For those not familiar with roasting, why is this important?

ET: Currently, we can actually see if we roast the same coffee to the same temperature with the same overall roast time by looking at two profiles, one having the majority of development time (more weight loss/moisture loss) in the 310-340 degrees Fahrenheit (bean temp) range and one with the majority of development time (more weight loss/moisture loss) in the 380-410 degrees Fahrenheit (bean temp) range. The one with more development time—310-340 degrees Fahrenheit—will most likely be flatter in the cup, leaning more toward a “baked” profile and lack of acidity. The batch with more time—380-410 degrees Fahrenheit—would most likely have more acidity but lean toward an astringent cup.

To make the concept even more confusing, different coffees react differently to weight loss due to bean density, the roaster’s ability to provide heat penetration through the bean, green coffee moisture content, and age of the green coffee. So the questions are: Why do coffees taste different when the same coffee is roasted with the same amount of overall weight loss, roast time, and drop temperature? And, how does weight loss over different temperature ranges affect the cup profile?

I believe most roasters would say that all of the above are relevant and have their reasons for believing so. This is why we have roast profiles. However, I don’t know of anyone with the capability to actually track this data in order to come up with a consistent rationale for their adjustments. With real-time weight loss data, we will be able to dial in roast times during roasting and have some real correlations between development time, weight loss, heat transfer, and how these things affect flavors during different stages of roasting.

SR: What is a wet scrubber? How will this replace the afterburner?

ET: For pollution control, [since we’re] being essentially mandated by the county to use around 10 times the fossil fuel to run a thermal oxidizer (afterburner) in order to control the emissions out of our roaster, smoke has never made environmental or any sense to me or Boyd for that matter. Of course there are options like an electrostatic precipitator and catalytic oxidizers, which use less gas or electricity. Typically these methods have lower NOx output and are more efficient; however, the costs of these systems are often preventative and still typically consume more fuel than the roasters they are “cleaning.”

With these things in mind, Boyd and I came up with an alternative: the wet scrubber. Scrubbers are used in many industries to clean emissions including petroleum refineries, chemical processes, acid manufacturing plants, and steel making, so why not coffee roasting? Scrubbers are effective at removing both gasses and particulate from exhaust. They do this by essentially “washing” the exhaust with water, typically. In a nutshell, exhaust enters the scrubber chamber while a fine mist of water is sprayed constantly into the chamber, dropping the temperature of the exhaust and binding particulate, oils, and gasses to the water and/or making them heavier than steam, which forces this “sludge” to drop out or fall out of the exhaust.

Renegade’s scrubber will have a recirculating pump and filter that will recycle about five gallons of water per hour. The organic sludge that will be created from the scrubbing process will be either pumped to our flower beds or barreled for a local bio-fuel company to pick up and recycle. On top of the environmental plusses, my rough calculations show running costs of the Renegade scrubber versus a thermal oxidizer will save us about $100k a year on an eight-hour-a-day, five-days-per-week operation schedule.

SR: When do you hope to be up and running on the new roaster?

ET: The simple answer is yesterday! Sadly, things don’t work easily when permitting and developing new equipment, as many people know—especially when dealing with the city, county, and air quality management. All that being said, realistically, we will be up and running in September or October 2017, but we will be doing everything in our power to make it sooner.

SR: Is there anything else you want the specialty-coffee industry to know about Temple, your new roastery, or what to look for in the future?

ET: As Temple expands and increases volume, I am constantly thinking of ways to increase production, maintain quality, and run more efficiently, as all companies do as they grow. This dilemma was really the driving factor of many of the technologies being put into the new roastery space.

As coffee companies expand and increase their volume, I don’t think it’s 100 percent necessary to take cuts in quality to increase efficiencies and/or margins; you just have to plan accordingly for them years in advance. I have always believed this was the case, and our new space should help prove this. I’ve been in coffee and will continue to work in coffee because I believe our industry is full of and built on people who share ideas to push the envelope of what is normal. This goes for our partners in producing countries and even the customers who are enjoying our final product.

ABOUT THE AUTHOR

ABOUT THE AUTHOR

Sarah Richmond relocated back to the Bay Area to manage and operate Bay Area CoRo in 2016. Her experience as a roaster, wholesale director, production manager, barista trainer, and writer affords her over a decade of experience in specialty coffee. Sarah’s bi-coastal work experience inspired a deep appreciation for writing about coffee culture and the ever-growing, ever-changing industry. She is currently serving on the National Editorial Advisory Board for Barista Magazine and can be found hiking up the nearest trail, mountain, or hillside when she’s not playing coffee.