We learn about the nuances of keeping these energy-efficient coffee roasters in the best shape possible.

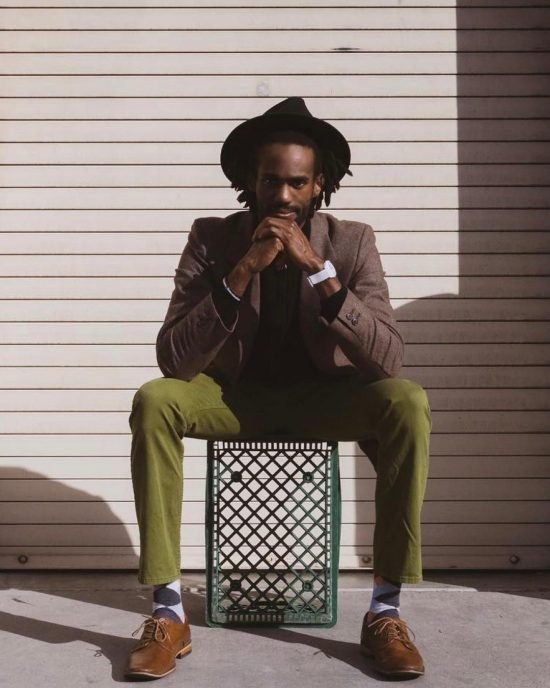

BY SPENCER AUBREY

SPECIAL TO BARISTA MAGAZINE ONLINE

Photos courtesy of Bellwether Coffee

Bellwether Coffee makes a commercial roaster built for environmental sustainability. With its futuristic features, it may be a little daunting to learn the ins and outs of caring for this machinery compared to other standard drum roasters. We spoke with a Bellwether rep to better understand the complexities of this machine, and what kind of unique maintenance it may need as a novel piece of coffee equipment.

About Arno Holschuh, Chief Coffee Officer

Arno Holschuh is the chief coffee officer of Bellwether Coffee. A skilled conversationalist, he was one of the early hires at Blue Bottle Coffee, serving as the vice president of production, and has been involved with the specialty-coffee community since early 2004. Arno received his BA in Political Science and Government and German Language and Literature from Northwestern University. In addition to his role at Bellwether, Arno is a member of the Coffee Technicians Guild.

Barista Magazine: How much green coffee do both the hopper and the drum hold? What would the ideal output per hour be in kilograms for full batches?

Arno: The roaster is currently designed to perform best at six-pound batches. The question of batch size is about more than hopper size or drum size; it also has to do with how much heat and airflow the roaster can provide. At six pounds, the roaster can hit anything from very aggressive roasts (think first crack in seven minutes) to much slower, stretched roasts.

The ideal throughput for the roaster is about 12 pounds green, or 5.5 kilos. With the natural weight loss that occurs during roasting, this will produce around 10 lbs, or 4.5 kilos, of roasted coffee per hour.

Where does the hot air from the roaster go if there’s no exhaust system required? Will it just be released into the café and make it hot?

Our roaster makes headlines because it has a tiny carbon footprint and can be placed almost anywhere. But the underlying technology that makes both of those possible is recirculating roasting. Most roasters pull in air from the environment and heat it to somewhere between 450°F and 600°F, and then use that to heat the beans. This makes the air smoky so they, naturally, get it out of the space through a chimney. Our roaster takes that hot, smoky air and cleans it through a managed catalytic process. This hot clean air is then reused to heat the beans again.

This has tremendous benefits. First, no hot air goes into the environment, so the café doesn’t get hot. Second, it is a much more efficient design because you are not constantly pushing heat out of your exhaust stack — you can retain it for more work. Third, the Bellwether’s lack of reliance on constant fresh air means it is far less susceptible to changes in environmental conditions like temperature and humidity. It’s like an espresso grinder that never needs to be dialed in.

How much electricity is used and heat generated by the machine? How loud is the machine?

The machine’s theoretical peak load is around 10 kilowatts, approximately what a four-group espresso machine would pull. It generates a lot of heat, but that heat mostly stays within the machine. Our roaster is very well-insulated; some heat does escape, of course. We’ve found it puts out about as much heat into a café as a convection oven one might use for toasting sandwiches does.

The roaster is pretty quiet. If it’s the only thing on in your shop, or if you are standing right next to it, it’s audible. But, you can still carry on a conversation in normal tones while operating it. It’s nothing compared to steaming milk or grinding coffee.

What steps should users take to make sure the Bellwether is operating at its best?

There are some very basic daily maintenance tasks that take less than 10 minutes to complete. One needs to empty the chaff can, and one needs to empty a water reservoir that collects the moisture produced during coffee roasting. All other maintenance is performed by technicians.

How often does the software in the Bellwether need to be updated, and do users need to do it or does it happen automatically?

The software is updated as needed. It could be twice a month or once a quarter. The user shouldn’t have to do a thing other than power cycle the machine since updates are automatic. One notable exception is that the user must make sure to update the iOS on the iPad we use as a control panel for the roaster.

If there’s a problem with the machine, can our regular tech help solve it or do we need to contact Bellwether?

You will want to contact Bellwether. All our machines come with a two-year comprehensive warranty, so we arrange and pay for the service. Additionally, this is a new machine, so we work really closely with our techs to make sure they have the requisite knowledge to complete the repair.

That said, in most cases we would be happy to work with your regular tech. Almost all technicians in our network are primarily coffee technicians, and we want where possible to work with a person that is already known and trusted by you.

Are there any parts to the Bellwether that require regular service or replacement?

The roaster is designed to be maintained after a certain number of roasts are completed. Because we have good diagnostic data about the roaster, we can tell when maintenance is due and will reach out to schedule one. There are very few parts that we consider true wear-and-tear items. Most are in the system that treats the air used to cool the coffee—that system has filters to make sure that cooling air is fit to be released into your café.

ABOUT THE AUTHOR

Spencer Aubrey (he/him) is a Black coffee professional currently working for Sayso Coffee in Winston-Salem, N.C. Spencer is a published poet, musician, tutor, and aspiring entrepreneur who enjoys the complexities and nuances within the coffee community. Spencer is originally from Scottsdale, Ariz., but is enjoying his time in the South as he looks for opportunities to connect with folks during the pandemic.