We catch up with James, who has been visiting cities across the world to debut the Eagle One espresso machine with Victoria Arduino.

BY KATRINA YENTCH

BARISTA MAGAZINE ONLINE

Photos courtesy of the Simonelli Group

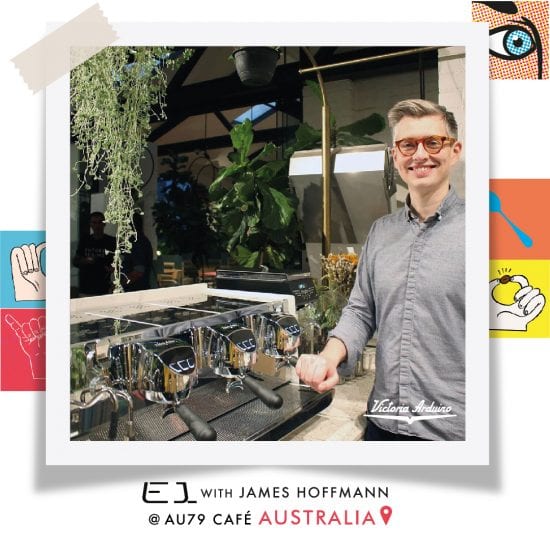

Coffee pro James Hoffmann and Victoria Arduino haven’t started a band together, but they are on tour to promote the launch of a chic, new eco-friendly espresso machine called the Eagle One. The tour kicked off in February with a visit to AU79 in Melbourne, Australia, and has since crossed continents into New Zealand, Indonesia, and today’s stop in New York City.

Sustainability is the focus of the Eagle One—which James had major involvement with as a consultant on the development of the machine. Its innovative engine reduces energy consumption through reduced heat dispersion. In addition to this, its minimalist design and compact size increase its accessibility to a wider audience of baristas and cafés.

James is a man of many projects, and this isn’t the first time he’s collaborated with Victoria Arduino/Nuova Simonelli on a product. He assisted in the company’s development of the Black Eagle VA388 in 2015, as well as the Mythos One grinder back in 2013. We spoke with James a little more about the features of the Eagle One, as well as how he has continued his approach from the previous two projects.

Katrina Yentch: This isn’t the first collaboration you’ve done with Nuova Simonelli/Victoria Arduino—or on an Eagle espresso machine. How did you both decide that sustainability would be the focus of this machine, as opposed to simplicity on the last one (Black Eagle VA388)?

James Hoffmann: The approach with new machines is first to consider the audience, and the issues/challenges/problems they might have. The Eagle One is designed for a much wider audience than the Black Eagle, and one big shared issue is most easily labeled sustainability. That word does come with multiple meanings; we all want to reduce our environmental impact, but more than that we want to reduce waste. Waste is an expense a business shouldn’t be paying and, in an incredibly competitive market for cafés, it’s an expense few can tolerate if they wish to build a financially sustainable business.

This also isn’t the first time that you’ve worked on a sustainability-focused piece of equipment (Mythos One grinder). How did you approach sustainability this time since you last worked on it? Has your approach changed?

I think this is very much a continuation of an approach. The problem we were tackling with the Mythos One is that grinders had been very wasteful. They needed adjusting often, and many required you to purge out a lot of ground coffee in order to properly see the impact of the grind setting change. It was slow, wasteful, and irritating, and a problem worth trying to solve.

What is one particular feature of the Eagle One that you spent a lot of time on that you’re excited to see play out in a café rush?

We spent a long time on the grouphead display, which I think they did a great job with. From an ergonomics and workflow perspective, I think it’s a fantastic little display with a great name. (It’s called the Ghost Display because it disappears completely when not in use).

To keep track of James’ stops on the tour, visit here for more updates.