How does hot air roasting work? With the guidance of First Crack Coffee’s Collin Bay, we explore this innovative roasting method.

BY TANYA NANETTI

SENIOR ONLINE CORRESPONDENT

Featured photo courtesy of Typhoon Roasters

Welcome to another installment of “Roasting Machines Explained,“ an article series wherein we explore the different types of roasting machines, and the benefits of working with each one. After learning the basics of drum roasting and wood-fired roasting, I decided to continue my journey of discovering different types of coffee roasting by moving to hot air roasting, one of the newest and, in my opinion, most interesting methods of roasting coffee.

Hot Air Roasting: An Introduction

Initially, the only thing I knew about hot air roasting was that it was first developed in the 1970s by Michael Sivetz, an engineer and inventor who was simply looking for a better and more efficient way to roast coffee. But aside from this small certainty, everything else was a big question mark for me, with one crucial question: When we talk about hot air roasting and fluid bed roasting, are we referring to the same technique? Apparently, the terms are used interchangeably on the internet, but I wanted to be sure before I went to find out more about it.

A quick conversation with Collin Bay, co-owner of First Crack Coffee, a company that provides co-roasting, white labeling, roast distribution, and coffee education, helped me resolve my doubt. “To simplify, we can say that air roasters and fluid bed roasters are the same thing. They refer to any type of roaster based to some extent on (Michael) Sivetz’s original design,” Collin says. “Then, there is a subcategory called convection roasters, which are basically modernized fluid bed roasters.”

Comparing Hot Air Roasters to Drum Roasters

Collin goes on to talk about the differences between drum roasters and hot air roasters, discussing how, while drum roasters tend to dominate the industry, hot air roasters can produce more consistent roasts.

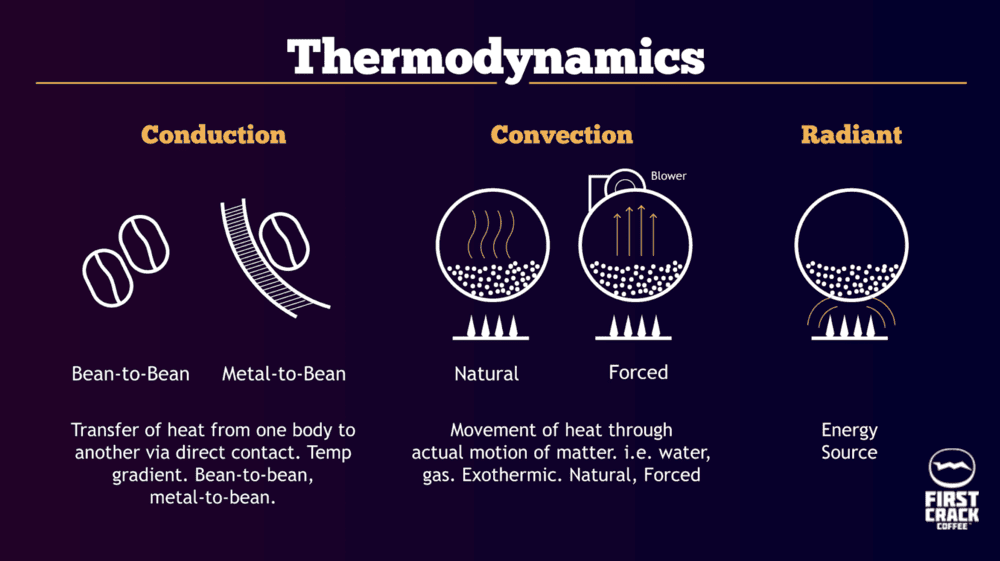

“Without going into the history of roaster technology, it is possible to consider drum roasters as the dominant type of roaster throughout history: The beans tumble inside a drum where they are heated primarily by conduction (heat based on contact) and partly by convection (heat through a fluid medium, in this case hot air),” he says. “Drum roasters use both natural convection and forced convection. The idea is that heat transfer by conduction creates body. It’s like putting a steak on a grill: The grill lines on a steak are where there is intense conductive heat transfer.”

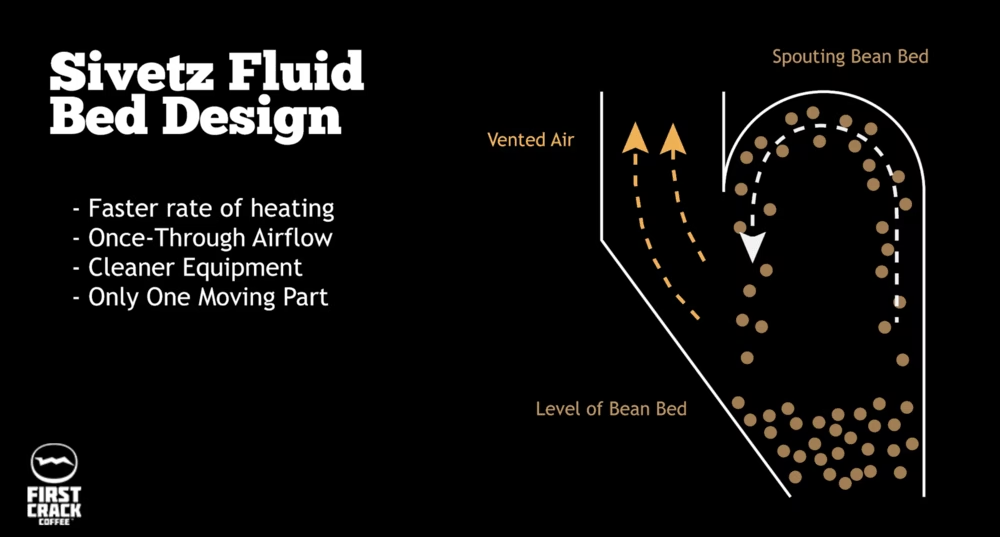

“In contrast, convective heat transfer has historically been thought to eliminate the problem of inconsistent roasts (outer to inner bean), but potentially at the expense of body construction. Taking a look at the Sivetz design, we can see that instead of having a drum, it uses a ’roasting chamber’ in which the beans are continuously pushed through the air by a very powerful blower,“ Collin continues. “The blower is inextricably connected to a very powerful burner, so there is essentially no heat transfer by conduction. This is what we still refer to when we talk about ’hot air roasting’ or ’fluidized bed roasting,’ (which are) interchangeable terms.”

Stay Tuned for More

Tomorrow, we’ll release part two of this article, where we’ll further explore hot air roasters and the benefits of working with one.

ABOUT THE AUTHOR

Tanya Nanetti (she/her) is a specialty-coffee barista, a traveler, and a dreamer. When she’s not behind the coffee machine (or visiting some hidden corner of the world), she’s busy writing for Coffee Insurrection, a website about specialty coffee that she’s creating along with her boyfriend.

Subscribe and More!

As always, you can read Barista Magazine in paper or digital format. Read the December 2024 + January 2025 issue for free with our digital edition.

And for more than three years’ worth of issues, visit our digital edition archives here.