Having trouble getting different groupheads on your machine to pull shots at the same rate and volume? Jon Ferguson troubleshoots the issue.

BY JON FERGUSON

BARISTA MAGAZINE ONLINE

Photos courtesy of Jon Ferguson

Have you ever imagined what it would be like to combine “Car Talk“ radio and “Dear Abby“ to create a column that focuses on coffee equipment service issues? Our new “Tech Talk Online” series might just be your answer!

In this biweekly column, equipment expert Jon Ferguson will be providing responses to common questions about coffee tech and helping troubleshoot issues that baristas, café owners, and other coffee professionals have about any and all coffee and brewing equipment. In today’s installment, he’ll be discussing what to do when different groupheads on your espresso machine aren’t pulling shots at the same rate or volume as one another.

Got a question for Jon about café equipment? Email techtalk@baristamagazine.com and let him know!

This Week’s Question: I have a two-group espresso machine where I can’t seem to get both groupheads to pull at the same shot time or volume. What’s going on?

Jon’s Response:

There are a few simple tests and inspections that you can easily do to narrow down some of the possibilities.

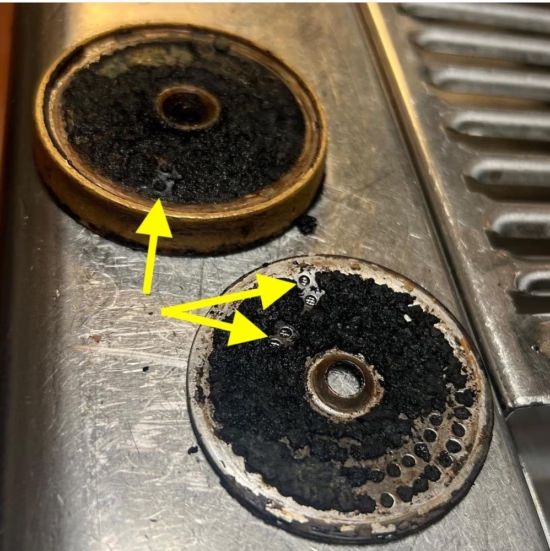

First, backflush your machine and remove the dispersion screen and plate (if applicable). If the screens look concave or well-used, now is a good time to replace them. Check your baskets and your portafilter condition. Ensure the spouts and pathway through the portafilters are clean. Take out the baskets, then clean them and compare them. Are they identical in basket shape, size, material, and brand? If in doubt, it is best to make sure by replacing with identical baskets if using both portafilters for each grouphead.

Next, if your machine has pressure or flow profiling features, verify that your programming parameters match for each grouphead. There could be a chance that a setting such as pre-infusion was adjusted or added to one grouphead without copying the recipe to the second grouphead. Verify that your programmed brew recipes are identical.

Lastly, conduct a manual flow rate test on each group head. You will need a small metric scale ideally with a tolerance of 0.01 grams, a vessel that holds up to 800 grams of water weight, and a digital timer. To start the test, remove the portafilters from the machine. Tare (zero out) the weight of the container to be used to catch hot water and place it under the first grouphead. Engage the brew button and let hot water freely flow into the container for 30 seconds. When finished, place the container of water onto your scale and write down the weight. (Repeat this process three times to get an average number.) For the second portafilter, repeat the entire process and compare water weights from both groupheads. If the resulting weights are within a tolerance of 5 to 10 grams of water weight, there is likely no major flow rate issue. If there is a significant difference, this could point to a clogged flow restrictor in one of the groupheads.

Espresso machines are unique in their use of flow restrictors, so much that people like to call them by several names, including gicleurs and jets. They come in different shapes and sizes, so flow rates from one machine will be different to the next. If a machine has recently had a jet replaced in one grouphead but not all of them, there could potentially be a mismatch in the sizes of the jets that were replaced; this would be a rarer occurrence, yet still possible. No matter what the situation is with a clogged jet, gicleur, or flow restrictor, a qualified service technician should be called to help remedy this situation. Locating, cleaning, and replacing flow restrictors can become a very complicated, dangerous, and warranty-voiding situation.

ABOUT THE AUTHOR

Jon Ferguson has nearly two decades of experience across various facets of the coffee industry. He believes that with a deeper understanding of equipment used throughout the entire coffee supply chain, we can gain a deeper respect for the labor and technology required to transform fruit seeds into the beverages we all dearly love.

Subscribe and More!

As always, you can read Barista Magazine in paper or digital format. Read the February + March 2025 issue for free with our digital edition.

And for more than three years’ worth of issues, visit our digital edition archives here.