Jon Ferguson answers your most pressing equipment-related questions. Today, we discuss reading needle gauges on an espresso machine.

BY JON FERGUSON

BARISTA MAGAZINE ONLINE

Images courtesy of Jon Ferguson

Have you ever imagined what it would be like to combine “Car Talk“ radio and “Dear Abby“ to create a column that focuses on coffee equipment service issues? Our new “Tech Talk Online“ series might just be your answer!

In this biweekly column, equipment expert Jon Ferguson will be providing responses to common questions about coffee tech and helping troubleshoot issues that baristas, café owners, and other coffee professionals have about any and all coffee and brewing equipment. In today’s installment, he’ll be discussing espresso machine needle gauges.

Got a question for Jon about café equipment? Email techtalk@baristamagazine.com and let him know!

This Week’s Question: What Do the Needle Gauges Represent on an Espresso Machine?

The Response from Jon

Much like the dashboard in your vehicle, these gauges are instruments that help you monitor the status of pressure for both steaming and espresso extraction, while also providing further technical insight on the operations of your machine.

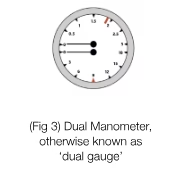

You will often find two gauges (i.e., manometers) responsible for monitoring steam and coffee boiler pressure. As shown in Figure 1, these two pressure gauges can be combined into a dual gauge.

The needles will often rest or fluctuate at set points, providing insightful information about the operations of the machine. To prepare the operator with a clear understanding of these gauges, we should first discuss the different measuring systems used for pressure: bar and pound-force per square inch (PSI).

Is Your Machine Measuring Bar or PSI?

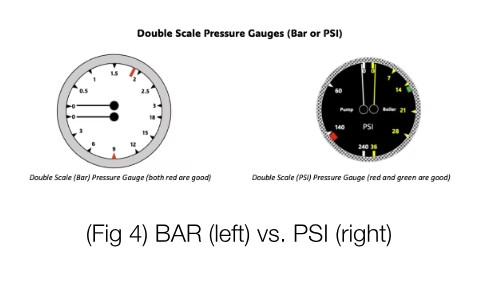

Bar is a metric unit of pressure measurement, while PSI is an imperial unit of measurement commonly found with machines manufactured in the United States. Espresso machine manufacturers historically have based their production in countries where the metric system is used, so a majority of espresso machines on the market tend to use bar as the measurement unit of choice.

For the pump pressure on the left, we see a red mark noting the preferred set point for that machine to be at nine bar of pressure, while on the right we see a red market set just below 140 PSI. Although these numbers seem very different, they are nearly equivalent (i.e., nine bar = 130.534 PSI).

Not all machines are designed to be set at these specific reference points. Please reference your make and model and have a qualified technician verify which set points are best for your machine.

Why Does My Machine Not Have Either of These Gauges?

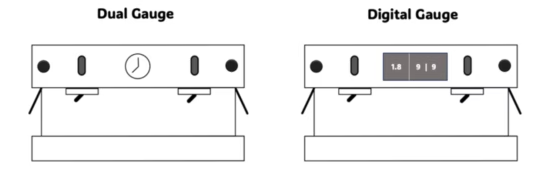

It’s possible your machine is using transducers (pressure sensors) to monitor pressure, rather than traditional manometers as shown above. These digital manometers are able to convert the reading into an electrical or electronic signal. Rather than looking at a needle gauge, the user will reference a touch screen where the information for both steam and brew pressure are displayed. With this technology, it will now be possible to make pressure adjustments through programming, rather than manual adjustments to components within the machine, which is typically serviced by a qualified tech.

Digital manometers can also help coffee service techs troubleshoot pressure issues from a remote location to possibly help save on service calls. Digital gauges also allow the user to record pressure activity, with the possible option to connect to data-logging software to replicate pressure profiles.

Conclusion

No matter how precise your grinder weight and distribution methods become, if flow rate and pressurization are not working properly, your efforts may become all for naught. If you would like to discover more, join Jon Ferguson at Coffee Fest New York in March for his presentation “Coffee Under Pressure: A Guide to Espresso Machine Ownership.“

Test Your Knowledge

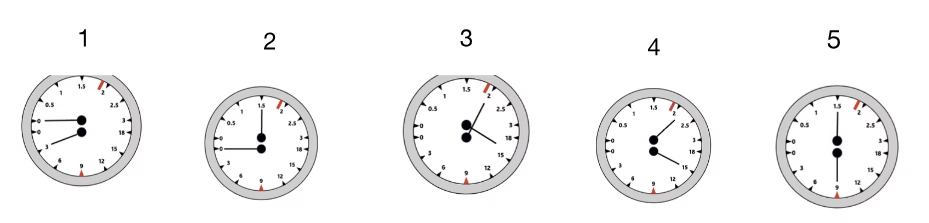

But for now, here’s a quick matching quiz! Try matching the following scenarios with the corresponding dual gauges.

*This is strictly for entertainment purposes only. The needle positions shown below do not guarantee or imply proper operation, correct, or incorrect positioning. Always consult directly with a qualified service technician for your espresso machine needs.

Set points for this demo machine are as follows:

Steam boiler = 1.5 bar

Coffee boiler = nine bar

________. Dual gauge is broken

________. Machine is pressurized properly

________. Water is connected, but no steam pressure

________. Water may not be connected but there is full steam pressure

________. Expansion valve and safety release pressure valve issues. Seek tech support. Dangerous.

ANSWER KEY

__3______. Dual gauge is broken

__5______. Machine is pressurized properly

___1_____. Water is connected, but no steam pressure

___2_____. Water may not be connected but there is full steam pressure

___4_____. Expansion valve and safety release pressure valve issues. Seek tech support. Dangerous.

ABOUT THE AUTHOR

Jon Ferguson has nearly two decades of experience across various facets of the coffee industry. He believes that with a deeper understanding of equipment used throughout the entire coffee supply chain, we can gain a deeper respect for the labor and technology required to transform fruit seeds into the beverages we all dearly love.

Subscribe and More!

As always, you can read Barista Magazine in paper or digital format. Read the December 2024 + January 2025 issue for free with our digital edition.

And for more than three years’ worth of issues, visit our digital edition archives here.