We continue our series on processing by looking at the lactic process, a complex method that can produce stunning results.

BY TANYA NANETTI

SENIOR ONLINE CORRESPONDENT

Photos courtesy of Felipe Sardi

A simple cup of well-brewed coffee can have endless variations of flavors and aromas, which are closely linked to the many different aspects of the coffee itself. Origin, varieties, processing, and roasting style all deeply influence the final cup, so it’s worth understanding these variables better, including coffee processes.

In addition to the more traditional processes (natural, washed, and honey), in recent years many different methods have begun to spread. Anaerobic, lactic, double- and triple-fermented, and thermo shock are just some of the newer coffee processing methods, and it seems that additional processing methods are constantly being developed and discovered.

Introducing the Lactic Process

To promote lactic fermentation, producers create an ideal environment for the growth of lactobacillus cultures, the same bacteria used in dairy production responsible for the creation of lactic acids. They do this by placing highly sugary coffee cherries in an anaerobic (without oxygen) tank and leaving them to ferment. They carefully control the process, checking pH levels, temperature, and oxygen levels to find the perfect conditions for lactobacillus to flourish and dominate the fermentation.

Felipe Sardi, co-founder of the coffee farm La Palma y El Tucan, helps us to understand more about the lactic process, starting with the origins of their lactic-processed coffee.

“When we started processing the coffee cherries in the wet mill, we instantly fell in love with the complexity of the entire process, and saw a huge potential to innovate and experiment,“ Felipe says. “We slowly started to understand that through fermentation we were in fact triggering a process of acidification and disintegration of sugars. As microorganisms feed on the sugars to produce ethanol, organic acids, and carbon dioxide, there is a decrease in the Brix levels (the indicator of sugar content) of the coffee mucilage, which is eventually removed.“

Felipe continues, “We noticed that by controlling the fermentation environment we could have a significant impact on the final results. In the first attempts, the temperature and humidity levels sometimes accelerated the process, ruining many batches (and) increasing the chance of fungus proliferation, which spoiled the fruit and left undesirable flavors as a result. Understanding and trying to control all these variables was eye-opening for us and helped us work towards the goal of obtaining different flavor profiles, which in turn has opened the doors to the world of the lactic-processed coffees.”

How It Works

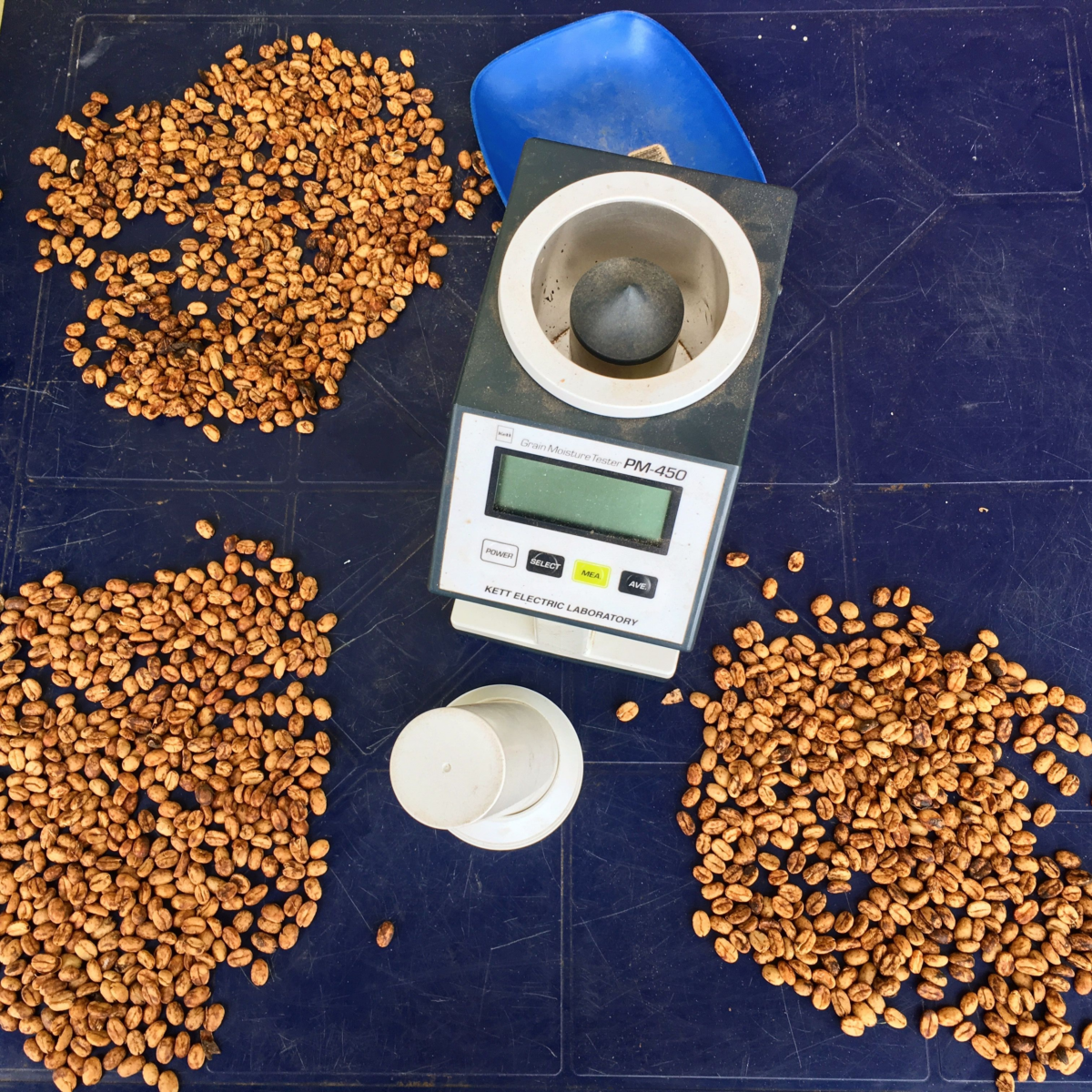

“This form of fermentation is classified as ’anaerobic,’ as oxygen has minimal interaction with the cherry and there is no agitation,” explains Felipe. “The coffee cherries are placed in sealed tanks after being hand-sorted upon arriving at the wet mill. The elimination of oxygen in this phase favors a greater concentration of lactic acid bacteria (and therefore of lactic acid) following the fermentation of the carbohydrates of the mucilage, which in turn contributes to the organoleptic profile of the resulting cup. The coffee cherries that will be processed with the lactic-fermentation method usually enter our wet mill with high Brix degree and pH readings, as these conditions will help the fermentation process to overcome the minimum time of 80 hours necessary for any lactic process.“

Lactic processes usually increase the perception of the body in the brewed cup profile. For this reason, the lactic process is most often utilized on coffee cherries from high-altitude farms; these cherries usually contain more mucilage, which helps balance the flavor profile of the resulting coffee.

Potential Challenges

Like all other processing methods, the lactic process can be difficult to execute, and has some possible downsides.

“One of the threats (from a producer’s point of view) of exploring lactic processes is the difficulty in avoiding phenols and over-fermented coffees,” Felipe says. “Due to the long times that we extend the pulp fermentation, as well as the moisture content control that we need to follow during drying, this is a very risky coffee process. The fermentation and drying times change with the different temperatures, humidity levels at the farm, and the (number) of kilograms in every batch.“

With so many variables to account for, a lot can go wrong. Felipe says that creating a ”recipe” for the perfect lactic processing method is complex. ”Pushing the limits of lactic processing too much may result in overwhelming bitterness and unbalanced cups, as we’re heavily affecting the perception of body over other attributes such as acidity and sweetness.”

If all goes as planned, however, a lactic-processed coffee will produce a very sweet cup with a medium-high body. It will have a strong lactic acidity profile, tropical fruit flavors/aftertaste, and a finish that can recall the flavor of papaya or pineapple yogurt. When producers succeed in performing the lactic process, the results can be incredibly rewarding.

ABOUT THE AUTHOR

Tanya Nanetti (she/her) is a specialty-coffee barista, a traveler, and a dreamer. When she’s not behind the coffee machine (or visiting some hidden corner of the world), she’s busy writing for Coffee Insurrection, a website about specialty coffee that she’s creating along with her boyfriend.