We review some takeaways from a workshop on coffee grinding that took place at this summer’s World of Coffee event in Athens, Greece.

BY TANYA NANETTI

SENIOR ONLINE CORRESPONDENT

Photos by Endri Nonaj

One grinder for home brewing may be sufficient. But it is certainly not enough in the daily routine of a busy coffee shop, where one or more grinders are often needed for the espresso bar, as well as for the brew bar.

But how do you choose a grinder wisely? How do you know which ones are best for home use, or for a new coffee bar?

To answer some of these questions, I attended the workshop “Coffee Grinding—From Burr Design to Maintenance and the Improvement of Cost of Business,“ given by Ansgar Bitz and Luca Lange of Hemro (a company that groups several brands of coffee grinders, including Mahlkönig) during World of Coffee in Athens, Greece, in June.

Grinding 101

After a brief introduction of all participants, the workshop began with a “Grinding 101“ section to introduce coffee grinding in general. First was an overview of why to grind: to increase the extraction surface of the coffee bean, promoting greater extraction and release of flavors. Then Luca explained different grinding technologies: conical burrs, flat burrs, and roller mills. Next, he discussed the materials of the grinding discs, which will vary based on the quality of the material and the market for which the product is intended.

Luca then continued with an in-depth explanation of the grinding stages: crushing, cutting, and finishing, achieved by coarse, middle, and fine teeth, respectively. He followed by explaining burr geometry, dwelling on the number and type of the burrs’ teeth, which are of paramount importance! They define the particle size distribution, grinding speed, and cost of both burrs and mills.

Workflow and Comparisons

The second part of the workshop, “Workflow and Milestones,“ began by briefly covering the evolution of coffee grinders, from manual to electric, with further advances such as dosers, grind-on-demand, and grind-by-weight. Then Luca analyzed how different grinder designs can affect both the sensory experience and workflow of a coffee shop.

At that point, it was time to start blind-cupping some coffees, to compare the different results of grinding the same coffee, at the same grind size, with two different types of grinders.

We didn’t know which cup was which, but we knew what to look for. One of the coffees had been ground with a grinder with horizontal burrs, usually used for espresso, and was supposed to provide more fines, giving more body and a more even and balanced cup.

The other, with vertical burrs (such as the classic Mahlkönig EK43, found in café brew bars around the world), was supposed to have more uniformity of particles, with fewer fines. This results in a thinner cup, highlighting both the good and bad qualities of the coffee.

After this explanation, it was easy enough to assign each cup to its specific grinder, even though we all had different preferences about which of the coffees tasted better.

This is why, Luca said, you cannot design a grind for taste: Taste is a personal perception. However, you can design a grind for the specific characteristics of the recipe.

Considering Costs

Luca continued with part three, “Cost of Business,“ by comparing two Mahlkönig grinders (the E80S and E65S). He discussed how to properly choose a grinder, taking into account its performance characteristics and upfront cost, the volume of coffee used daily in a given coffee shop, and the cost of spare parts, necessary maintenance, and so on.

Grinder Care

The fourth and final part, “Grinder Maintenance,“ began with a section on burr calibration, regular cleaning, and maintenance (both preventive and reactive).

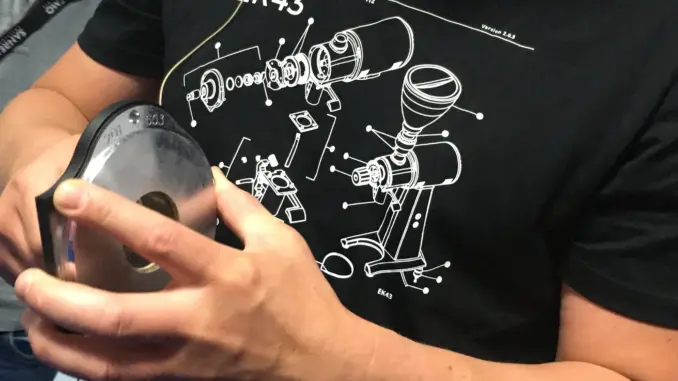

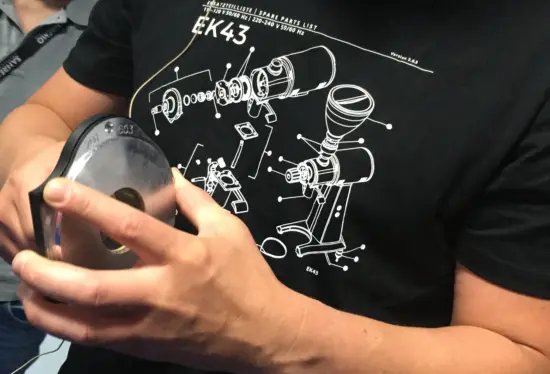

At that point, the workshop was almost at an end, but there was still time for the practical part, led by Ansgar, who explained and showed us—clearly and effectively—how to properly disassemble, clean, align, and reassemble an EK43 and an E65S. Personally, I found this part very useful, because learning how to take care of a grinder helps me become a more knowledgeable and well-rounded barista.

Overall, it was a really interesting workshop that, by helping us to better understand what is behind a grinder, taught us how to correctly choose one when needed.

ABOUT THE AUTHOR

Tanya Nanetti (she/her) is a specialty-coffee barista, a traveler, and a dreamer. When she’s not behind the coffee machine (or visiting some hidden corner of the world), she’s busy writing for Coffee Insurrection, a website about specialty coffee that she’s creating along with her boyfriend.

READ THE LATEST BARISTA MAGAZINE

Out now: It’s the August + September 2023 issue of Barista Magazine, featuring Boram Um of Brazil on the cover. Read it for free with our digital edition. Get your Barista Magazine delivered; start a subscription today! Visit our online store to renew your subscription or order back issues.